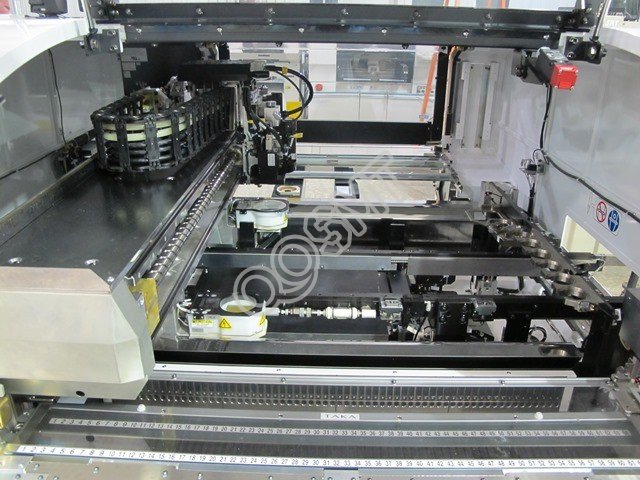

1.1 Placing heads ("auto-tools") are exchanged automatically during production:The XPF is the world's first machine to feature dynamic head exchange.The machine can switch between a high-speed placing head and a multi-purpose head automatically during production to ensure that the most efficient head for the current task is being used.This includes the ability to switch to a glue head, meaning that glue application and part placement can be performed at the same machine.

1.2 No need to decide between a high-speed mounter or multi-purpose machine:Because head exchange is dynamic and automatic, the XPF is a borderless solution, covering high-speed and multi-purpose needs at the same time.Whatever the type of panel, the XPF achieves the optimal balance of production capability, ensuring that you always get the most out of your equipment.

1.3 Support for panels up to 686 x 508 mm with the XPF-W:The XPF-W model is designed to handle large and heavy-duty panels with dimensions up to 686 x 508 (27 x 20 inches) mm and weighing up to 6 kg.

-

Specifications

-

|

Machine Specifications |

Revolver Auto-tool |

Single Nozzle |

M4 Auto-tool |

Glue Auto-tool |

|

Number of nozzles |

12 |

1 |

4 |

Number of syringes loaded :

1 syringe per glue station |

Number of auto-tools

held in auto-tool station |

2 (XPF-L) / 3 (XPF-W) |

6 (XPF-L) / 8 (XPF-W)

(One Tray Height Measurement Auto-tool

is held when using trays) |

1 |

Number of feeder slots occupied: 8 (MFU-40)

(Fixed loading position - up

to 4 glue auto-tools

can be loaded) |

|

Supported parts |

0402(01005) to 20 x 20 mm

Maximum height: 3.0 mm |

1005(0402) to

45 x 150 (68 x 68) mm

Maximum height: 25.4 mm |

4 nozzles type: 3 x 3

to 14 x 14 mm

2 nozzles type: 14 x 14

to 22 x 26 mm

Maximum height: 6.5 mm |

Loading side: Side 1

(MFU-40 or fixed device) |

Machine

tact |

XPF-L |

0.144 sec /

component 25,000 cph |

0.400 sec /

component 9,000 cph |

4 nozzles type: 0.343 sec/

shot 10,500 cph

2 nozzles type: 0.456 sec/

shot 7,900 cph |

Dispense tact: 0.2 sec/shot |

|

XPF-W |

0.145 sec /

component 24,800 cph |

0.418 sec /

component 8,600 cph |

4 nozzles type; 0.351 sec/

shot 10,250 cph

2 nozzles type; 0.462 sec/

shot 7,800 cph |

Placing

accuracy |

Small chip parts |

+/-0.050 mm cpk≥1.00

+/-0.066 mm cpk≥1.33 |

+/-0.040 mm cpk≥1.00

+/-0.053 mm cpk≥1.33 |

- |

Dispense position accuracy:

+/-0.1 mm cpk≥1.00 |

|

QFP parts |

+/-0.040 mm cpk≥1.00

+/-0.053 mm cpk≥1.33 |

+/-0.030 mm cpk≥1.00

+/-0.040 mm cpk≥1.33 |

+/-0.040 mm cpk≥1.00

+/-0.053 mm cpk≥1.33 |

|

PCB size (LXW) |

Up to 457 x 356 mm Thickness 0.4 (0.3) to 5.0 mm (XPF-L) / 686 x 508 mm Thickness 0.4 to 6.5 mm (XPF-W)Min 50 x 50 mm |

|

PCB loading time |

1.8 sec (XPF-L) / 3.5 sec (XPF-W) |

Machine

dimensions |

XPF-L |

L: 1,500 mm, W: 1,607.5 mm, H: 1,419.5 mm (Conveyance height: 900 mm H: excludes signal tower) |

|

XPF-W |

L: 1,500 mm, W: 1,762.5mm, H: 1,422.5mm (Conveyance height: 900 mm H: excludes signal tower) |

|

Machine weight |

Machine body XPF-L: 1,500 kg / XPF-W: 1,860 kg

MFU-40: Approx. 240 kg (with W8 feeders loaded)

BTU-AII: Approx. 120 kg, BTU-B: Approx. 15 kg, MTU-AII: Approx. 615 kg (with trays/feeders loaded) |

|

Parts Packaging |

|

Tape parts (JIS standard, JEITA), stick parts, tray parts |

|

Options |

|

Stick Feeder, Wide Fiducial Camera, Dip Flux Unit, Reel Set Stand (within the main machine), Lead Coplanarity Check, Custom Nozzles and Mechanical Chucks, Fujitrax |