The relationship between the basic properties of PCBA solder and assembly welding and its case description

Jan 25, 2024

Preface

Various phenomena occur during soldering. If you do not understand these phenomena, you will not know how to investigate the cause once a problem occurs, and therefore you will not be able to find the correct method to make thorough improvements. It is more likely that defective products will be shipped without knowing the truth, causing problems or accidents in the market.

Today, we will sort out and review the phenomena that occur during assembly welding of solder and the related solder material properties. It is hoped that readers can understand these phenomena and learn from them to judge the basic properties of solder welding.

1. Heat of fusion and heat of solidification

• Basic properties

The amount of heat required to heat 1g of water from 14.5 degrees to 15.5 degrees is called 1Cal. Ice needs to absorb heat when it turns into water. In the same way, solder also needs to absorb heat when it melts. For example: the heat of fusion of tin is 14.5cal/g. On the contrary, the same amount of heat will be released when it solidifies from the molten state, but at this time it is called the heat of solidification.

• Relationship with soldering:

During wave soldering and reflow soldering, the substrate and parts will be heated. Because each material absorbs heat at different rates, slowly and evenly increasing the temperature is an important process technology.

During cooling, the substrate and parts must be cooled evenly.

In contrast, when repairing with tin wire welding, because only the soldering pad is heated, the heat supplied by the soldering iron will be immediately taken away by the parts and the substrate. Therefore, the front end of the soldering iron must be raised to above 390 degrees to avoid poor soldering iron. No matter how the solder melts and solidifies, attention must be paid to the heating and cooling conditions.

2. Proportion

• Basic properties

When multiple metals are melted in a general melting furnace at the same time, the metal with a greater specific gravity sinks more. Therefore, the longer the melting time is, the more obvious this phenomenon will be when stirring is insufficient.

element chemical symbol specific gravity

germanium Ge 5.36

germanium Ge 5.36

antimony Sb 6.62

Zinc Zn 7.13

tin Sn 7.3

nickel Ni 8.9

Copper Cu 8.96

bismuth Bi 9.8

Silver Ag 10.49

Lead Pb 11.34

gold Au 19.32

• Relationship with soldering:

In tin-silver solder, the α phase is mainly the phase containing more silver, while the ß phase is the phase containing more tin. Therefore, when observing the cross-sectional structure of the welded part, if the α phase is at the bottom, it can be inferred that the time in the molten state is too long or the temperature is too high.

Alpha phase sinks

3. Volume shrinkage rate

• Basic properties:

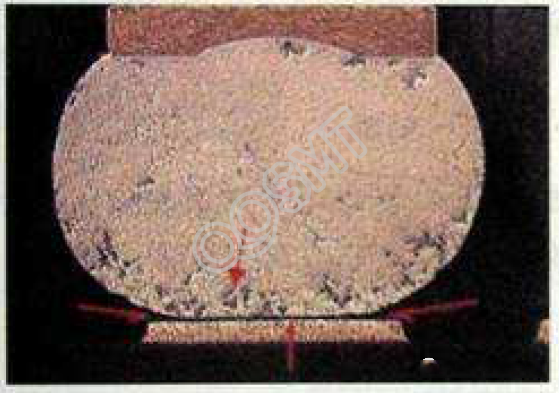

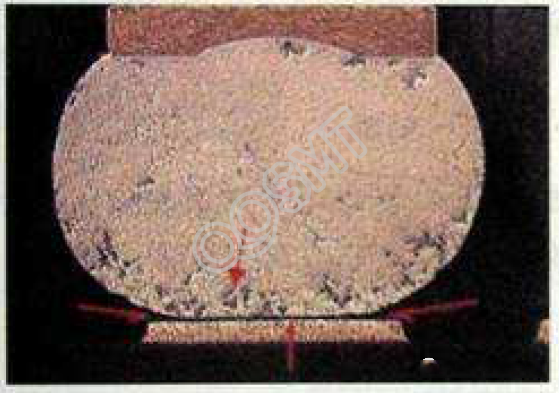

All substances expand when the temperature is too high and contract when the temperature is low. Especially when solidifying from a molten state, except for a small amount of substances, the amount of shrinkage caused by solidification will be larger and more obvious due to changes in cold and heat. The picture below shows the solidification and shrinkage of BGA (actual object)

Unused lead-free BGA balls

Metal Melting point (degree) Shrinkage during solidification a (%) Solidification-->Normal temperature b(%) a-b(%)

tin 232 2.8 1.41 4.21

bismuth 271 -3.32 1.01 -2.31

lead 327 3.44 2.63 6.07

Zinc 419 6.52 4.5 11.00

Antimony 631 -0.95 2.1 1.05

silver 960 5.00 5.83 10.83

gold 1063 5.17 4.5 9.67

copper 1083 4.05 5.97 10.02

iron 1530 4.4 5.93 10.33

• Relationship with soldering:

The volume change when cooling from the solidified state to room temperature is one of the important reasons for BGA open. If a large amount of α phase is concentrated on the PCB pad side, the volume shrinks greatly during cooling, which can easily cause Open. Similarly, the volume shrinkage during cooling is an area that requires great attention in the lead-free soldering process.

4. Heat release, heat absorption, contraction, expansion

• Basic properties:

The molten metal will begin to cool from the point where it gives off the most heat and will begin to shrink from that point. On the contrary, expansion and melting start from the place where the heat is most easily absorbed.

• Relationship with soldering:

Welding technology is a cooling technology that heats the solder to melt it and solidifies it in the expected form after welding. In a nutshell, welding is a comprehensive technology of heating and cooling. Factors to consider include the appropriate circuit design of the PCB board, the heating method, and the selection of solder materials.

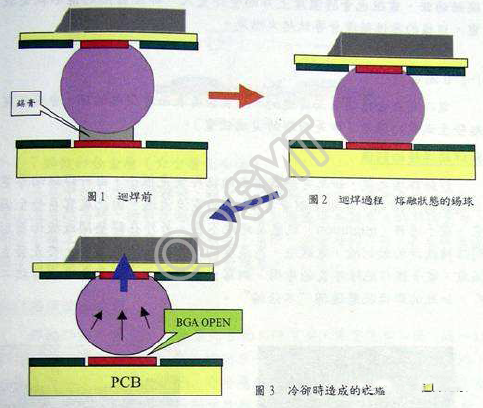

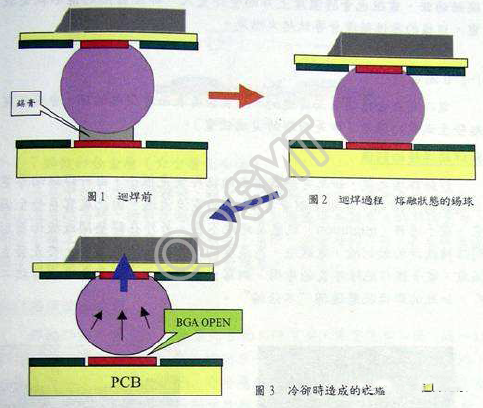

As shown in Figures 1 to 3 below, discuss the cooling situation when a BGA component is welded to a PCB board. If rapid cooling starts from the BGA side, the tin-lead solder will shrink in volume by about 5%; while in lead-free solder, there will be more drastic changes in appearance and volume shrinkage than this. The soldering strength on the BGA side of the part is high, but if the soldering pad on the PCB side has poor wettability due to contamination, etc., the shrinkage stress that the solder interface can withstand during solidification shrinkage will open from the PCB side. The cause of Open on the PCB side is mostly due to poor design and contamination of the circuit pads (residues of water-soluble flux used in tin spraying, gas generation caused by poor surface grinding of the PCB board, etc.). The reason why Open occurs on the BGA side can be attributed to poor surface grinding of the substrate, poor management of the electroplating process, etc.

5. Resistance

• Basic properties

Compared with copper, the resistance of solder is about 10 times that of copper. On the other hand, the current flowing through solder is only about 1/10 of that of copper. In addition, when the temperature rises to 100 degrees, the resistance of solder becomes twice that of room temperature.

• Relationship with soldering:

From the relationship Ώ=ßxL/A (resistance is proportional to the resistance and length of the metal, and inversely proportional to the cross-sectional area), in circuit design, if the soldering pad is made smaller, the temperature of this part will easily rise during welding Heat can even cause melting or fire. Once heating begins, the resistance will become larger as the temperature rises, and the heating situation will become more serious. Such a vicious cycle can lead to fires.

6. Leakage

• Basic properties:

Electric current is transmitted on the surface of the metal. If there are protrusions on the metal surface, leakage will occur from the protrusions (the so-called tip discharge).

• Relationship with soldering:

After soldering, if there is copper exposed, even if it is very small, since the conductivity of solder is 1/10 of copper, 10 times the current will flow through copper. Leakage, electron migration and poor insulation are prone to occur here. In addition, when the etching solution, plating solution, and high-concentration active agent that should be cleaned remain between the soldering pads or between the round surfaces of the board, it is also a cause of leakage and poor electron migration. Where copper is exposed, it usually causes poor welding. Such a welding state is commonly known as "non-stick tin"

Photo 3: Slightly raised Photo 4: 3 enlarged

Photo 5: Insufficient cleaning Photo 6: The motherboard caught fire during use

Figure 4: Leakage

7. Diffusion and alloy layer (intermetallic compound)

• Basic properties:

When you add a small amount of sugar to water, the sugar dissolves completely. Sugar molecules diffuse in water, and diffusion occurs faster at higher temperatures. Usually the amount of diffusion is affected by temperature and time, and the same phenomenon occurs on metals. Diffusion occurs at the interface between solid and liquid metals, and even at the interface between different solids at high temperatures.

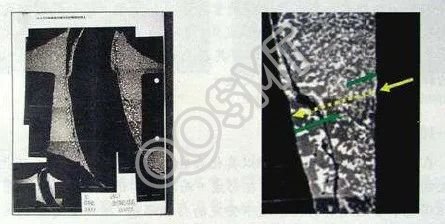

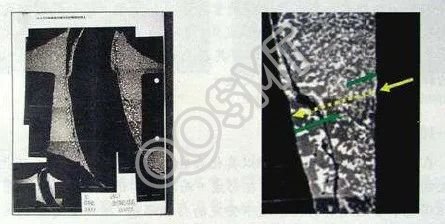

• Relationship with soldering:

The intermetallic compounds produced by solder welding are hard, brittle, and have poor electrical conductivity. When the temperature of the tin-silver-copper weld exceeds a certain temperature, the movement and diffusion of tin-copper atoms will become more intense, and an intermetallic compound will be formed after diffusion. Intermetallic compounds cause problems such as cracking and fire in the welded part. Therefore, the thinner the thickness of the intermetallic compound, the more reliable the interface will be. Looking at the cross-section of the welded interface, the ideal interface is when the thickness cannot be confirmed when observing with a metallographic microscope at approximately 1000 times magnification.

Photo 7: Intermetallic Compounds

8. Stress and coarsening

• Basic properties:

When an external force acts on a material, it will be transmitted into the interior of the material. When it encounters a harder part, it will be concentrated there. The concentration of stress increases the free energy there, causing instability in the physical and chemical properties.

• Relationship with soldering:

Figures 12 to 13 below show the static load acting on the solder, causing the structure to coarsen and crack (this is caused by the shrinkage of the filling resin during curing). In the electron microscope photo, the black part is the ß phase and the white part is the α phase. The arrows in Figure 13 below refer to the external force and the green arrow reaction force. As mentioned above, after welding, intermetallic compounds will be produced due to this substance. It is relatively hard and external forces cannot continue to be transmitted, so stress concentration occurs there, which increases the free energy in the area near the intermetallic compound and coarsens the tissue.

Photo 12: Fracture caused by static load Photo 13: Stress and coarsening of structure caused by stress

9. Generation of oxide film

• Basic properties:

For example, aluminum or stainless steel will produce an oxide film on the surface at the moment of oxidation. Since it is quite thin, it is difficult to observe. Melting point of solder-related oxides

tin oxide SnO2 1127 degrees

Copper oxide Cu2O 1232 degrees

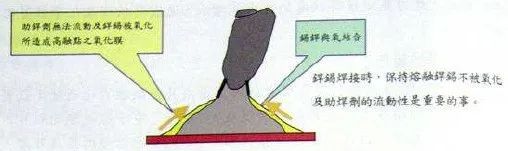

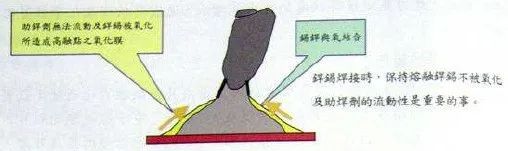

Figure 5: Occurrence of tin solder fillet (tin tip) and oxides

• Relationship with soldering:

Short circuits (bridging) often occur during welding, especially when hand welding. If you remove the soldering iron at the wrong time, the soldering iron will take away the flux, and the molten solder will be exposed to the air and the solder will be quickly oxidized to form an oxide film. If you observe carefully, as shown in the picture above, no matter whether the tip of the soldering iron is touched by solder or not, oxides will be produced on the surface and cannot return to the molten solder, forming horn-like protrusions.

10. Corrosion

• Basic properties:

Most metals on the earth's crust exist in the state of their compounds, such as sulfides, oxides, etc., which are formed in nature. Refining these compounds into metals, from the perspective of the natural environment, is to convert them into Unstable existence. Therefore, the metal will use the components of the environment to react with it and return to the stable form of the metal compound.

The forms of corrosion can be roughly divided into two types: dry corrosion and wet corrosion:

Dry corrosion: corrosion without the participation of moisture, such as AlàAl2O3 (aluminum oxide), CràCr2O3 (chromium oxide), which is called oxidation.

Wet corrosion: Corrosion involving moisture will accelerate the corrosion rate due to inorganic acids such as hydrochloric acid; organic acids such as Adipic acid. For example: the soldering parts of most electronic parts.

• Relationship with soldering:

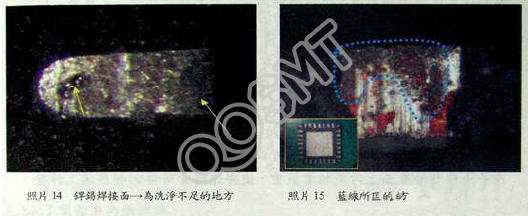

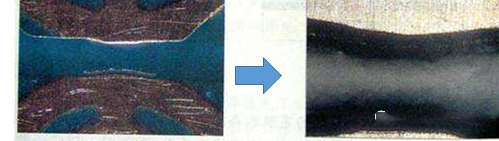

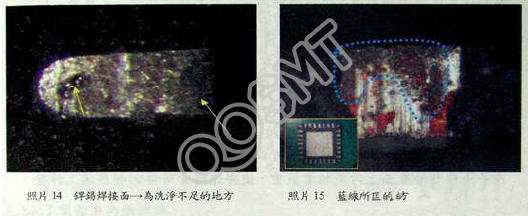

When poor wetting of part legs occurs, parts manufacturers often blame the assembly site for poor management of parts storage. In fact, these parts are not oxidized (such as dry corrosion) and should be regarded as corrosion (wet corrosion). Most of the causes of this form of corrosion can be attributed to poor management of plating and cleaning processes by part manufacturers, contaminants from poor mold cleaning during wire cutting and bending, etc. In particular, poor pin wettability is more likely to occur in parts factories. If the dirt in the mold is not removed, it will usually cause corrosion (not oxidation) of the pins. From the dirt-covered state of the unused parts in Figure 14 below, if the mold is not cleaned diligently during cutting and processing of such unclean pin lines, corrosion will occur in the part surrounded by the blue dot line in Figure 15 below, and during assembly Such corrosion can cause poor welding at the pin ends.

Photo 14: Soldering surface --> Insufficient cleaning. Photo 15: The part framed by the blue line is corroded.

11. Wettability and surface tension

• Basic properties:

When water is dripped onto oil-coated glass, the water bounces off into a non-spherical shape. If you use alcohol to remove the oil on the glass and then drip water, the water droplets will spread on the glass surface. This is called wetting. In terms of wettability, the smaller the surface force of a liquid, the easier it is to spread. On the contrary, the liquid is more likely to become spherical.

• Relationship with soldering:

If plating liquid, etching liquid, or water-soluble flux used in tin spraying remains on the metal surface on the soldering side, poor wetting will easily occur. The function of flux is to dissolve contaminants on the metal surface to improve the wetting effect, but too much flux can also cause poor welding. The surface tension of liquid metal changes due to different fluxes.

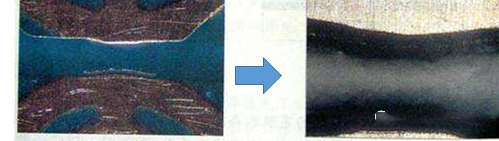

In principle, factors affecting wettability (dirty substrates, contaminated parts) must be removed at the assembly site. However, the general assembly factory will put the cart before the horse and blindly require the soldering factory to provide stronger flux to deal with the above problems, especially ignoring the insulation and requiring an increase in active dose. If we only focus on weldability and ignore the impact of environmental factors and reliability, it will often cause problems in the market. This is an issue worthy of understanding and consideration by assembly plants. •The wetting situation on the chip electrode as shown in Figure 16 below is quite good. But for the soldering pads, there is a phenomenon of tin springing. If it is a solder paste problem, solder pop-up should occur on the soldering pads and electrodes; but from the above phenomenon, it can be clearly understood that this defective phenomenon is caused by the soldering pads. As shown in Figure 17 below, there are obvious contaminants on the soldering pad. This is a residue caused by insufficient cleaning of the soldering pad surface with water-soluble flux during tin spraying, which in turn corrodes the soldering pad surface and further wets the solder paste flux. Capacity is reduced. In addition to the problem of insufficient cleaning, substrate factories must also pay attention to the substrate polishing and grinding process. In Figure 17 below, whether it has been cleaned or not, it can be confirmed that there is no flux residue on the surface of the soldering pad. This is because the surface of the soldering pad is so heavily polluted that even the solder paste flux cannot get onto the soldering pad.