* We will reply you within 24 hours.

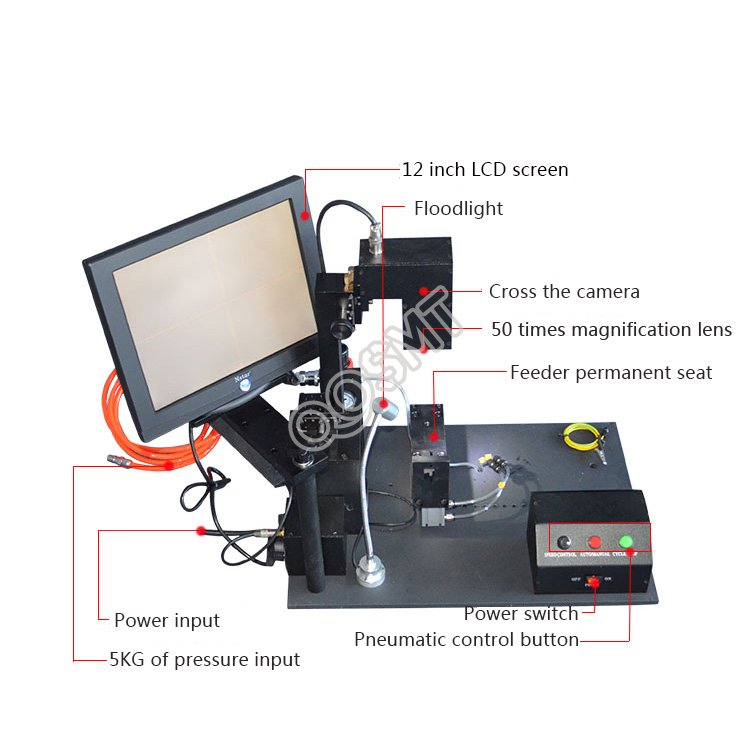

Feeder Calibration Machine for Samsung SM Pneumatic Feeder

Samsung SM Feeder Calibration

This product adopts CCD and 50 times the magnifying glass, observed by MONITOR feed, the thimble up and down movement, LEVER wear, reduce material frame caused by poor feeding problems, very good to improve the yield of the mount with help.

- Characteristic:

1.The operation is simple, the appearance is simple and compact.

2.The three shafts of X, Y and H adopt high precision gear drive,Precise and reliable.

3.50 times lCCD to make the picture clearer.

4.Equipped with a standard correction ruler to adjust the suction Center.

- To configure:

1.12 inch monitor

2.CCD fifty times zoom lens set.

3.1pcs Correction bar.

- Product installation

1.Please install the monitor on the disk and insert the CCD out signal line into the video signal input interface of the display. Connect the monitor to the 220V power supply

2.Turn on the CCD and monitor power, the monitor will have a cross cursor display; if not shown, please check the power and signal line is correct.

3.adjust the brightness and contrast of the display to display clearly.

- Product manual

1.Fit the calibration ruler to one of the best FEEDER in production and place the FEEDER on the placing platform

2.Adjust the focus H axis, so that the display to the FEEDER suction position, hole center, in the display of the cross cursor intersection to clearly visible, and then adjust the X, Y axis, so that the FEEDER suction position, small hole at the center of the display.

Safely Packaging

In order to ensure your shipments withstand the long trip and arrive safely and intact, QOSMT specially designed Individual package to pass the drop test with its stable structure.Besides,the package is made from recyclable materials, providing you with professional safety delivery.

Whether just single item or multi-products the clients buy, all products are packed twice to avoid the damage further.

Fast Delivery

Fast Cross-Border DeliveryQOSMT chooses DHL/FedEx/UPS as our main international express shipping partner. As the world's leading logistics specialist, DHL/FedEx/UPS provides our customers with fast and professional inter- national door-to-door delivery service.

Estimated Delivery Time: e.g. China-USA major cities 5 business days.

Professional

Warehouse Management